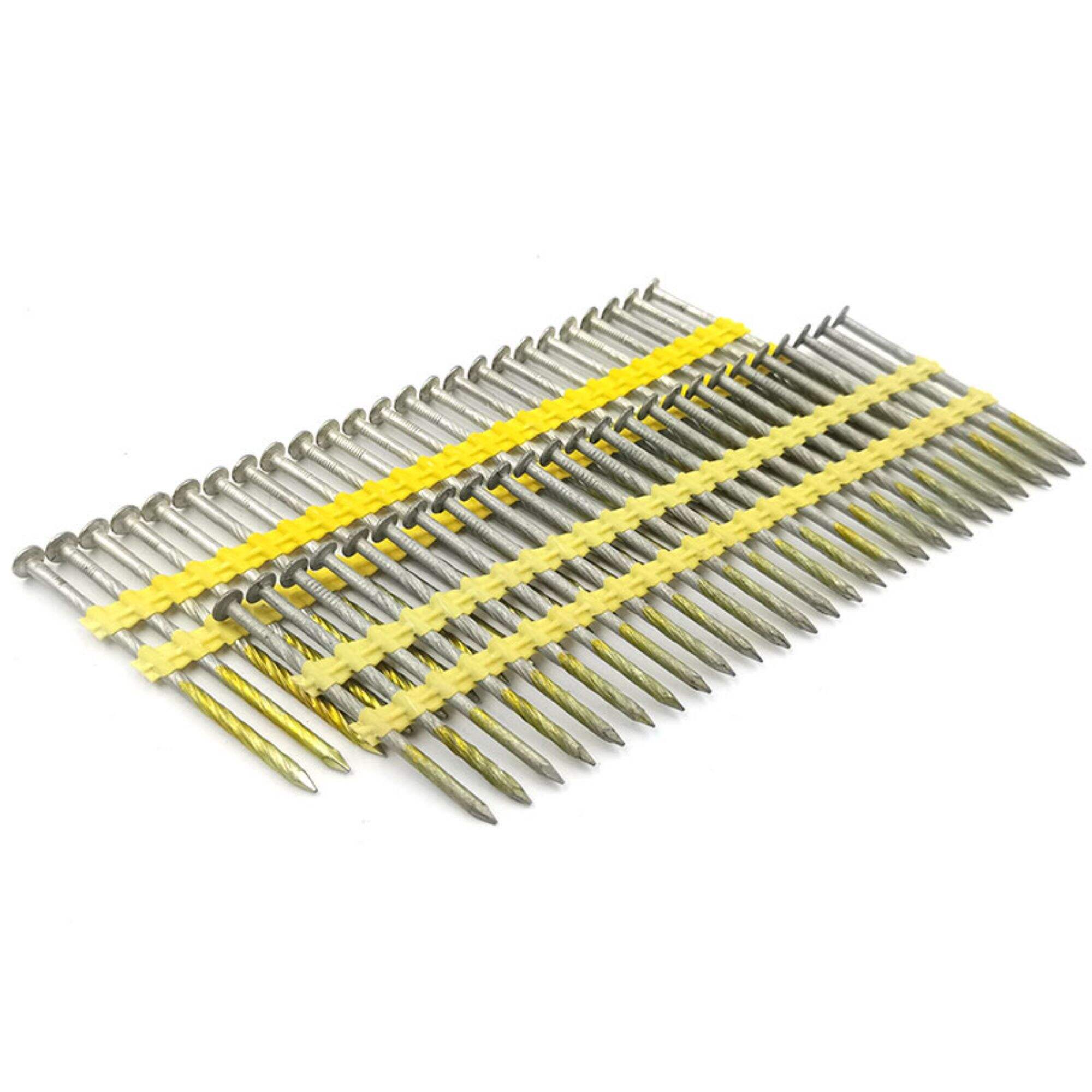

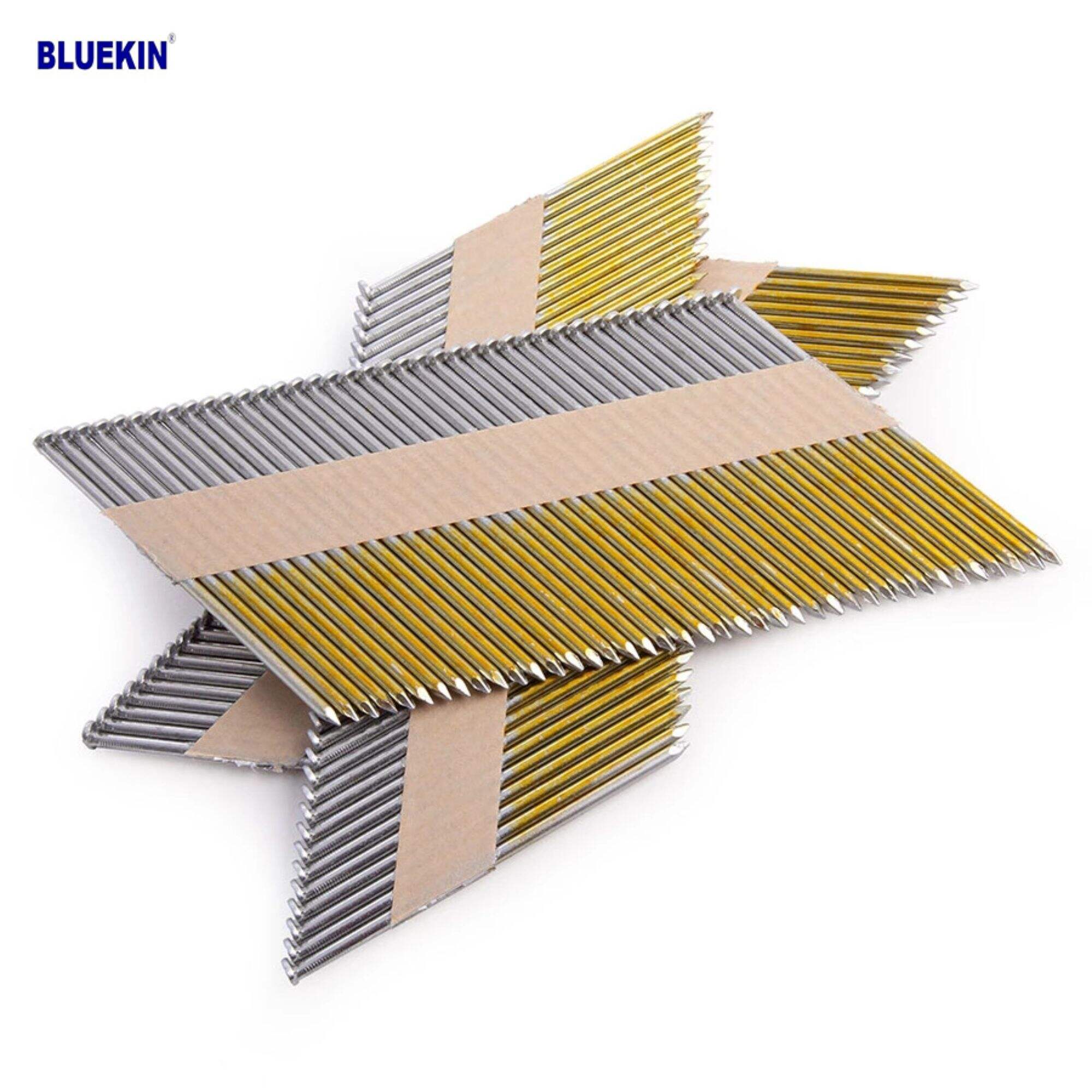

Tell me, have you ever seen a house or a building being built? When building houses or big objects like skyscrapers, people use wood, among many other materials. Nails are used to hold wooden planks together. In construction, certain types of nails are used; one of the most common types is the so-called “galvanized 21 degree framing nails. Framing nails heat treated andcoated to prevent rust. It is quite natural because nails face various weather conditions. A metal nail is stronger and does not get damaged due to water, and framing nails do not rust which can make it weaker. Therefore, the builders use galvanized 21 degree framing nails.

The "21 degree" is the uneven side of its designation which means that angle increases lean towards legs (» learn below this text). The head is the very flat, round part of a nail that sits above wood once you have hammered your nails. Which is a good thing because the angle at which you "strike head first" helps make your nail, bite into and hold on to, that wood faster. Therefore, it allows the nail to remain in its place and furthermore keeps everything a lot better together.

They are nails used in construction to join two pieces of wood together. A wall, for instance - you'd use these nails to fasten the studs (the vertical pieces of wood) into the plates (horizontal bits). This produces a rigid wall from which the rest of the building is supported. They may also, in this case for example be used to fix wood on concrete an extremely resistive material or to join the roof tiles to the walls. This is why they are so widespread in construction.

If using a framing nailer, 21 degree plastic or galvanized nails work the best and will not rust away for many years to come. They usually consist of strong, unbending metals like steel. The nails are manufactured, warmed until they are blistering underground resistance, and afterward an immense machine pounds them into the shape and size of sneer P. They are then coated with a zinc layer which prevents them from corroding. This procedure makes them incredibly dependable to developacing.

Using the correct size and type of nail is very important. So, if you use nails that are too small or weak to do the job properly it can cause weakness in the wood design. This could cause some trouble down the line, and if not fixed properly it can destroy a whole building.

When hammering nails in the wood, you should also be careful. You might split the wood or bend your nail if you strike it too hard, in a bad direction. This is hazardous and can weaken the building. When using a hammer and nails, it is recommended to work slowly;

can also provide user's manual installation videos. are able to galvanized 21 degree framing nailsreplacement in case the packaging is damaged or the product was damaged during shipping.

will begin production within matter hours after galvanized 21 degree framing nailsconfirmation of order.

galvanized 21 degree framing nailstalk about ODM OEM processing. 100 time delivery

products tested inspected prior to going to next phase, making sure that quality control is strict within the galvanized 21 degree framing nails.